Research and Development Facility

AWENTA has always endeavoured to manufacture products of highest quality. Achieving this would not have been possible without investing in professional measurement and laboratory equipment. The decision to build our own Research and Development Centre on the premises of our production plant has proved a milestone in achieving our product quality objectives.

Following the establishment of the CBR (Research and Development Centre), we have now been able to monitor the quality of our products and the entire production process even more closely, from material acceptance all through to shipping our finished products to our business partners. We make every effort to ensure that every single product is free of any defects. All accessories meet the strict regulations of European law, which we confirm with the required certificates and declarations of conformity. We constantly strive to improve our products by marketing new, even better solutions for ensuring more efficient ventilation. Our primary goals are to ensure our customers’ good experience using AWENTA systems, and to supply products that meet international quality standards.

The Research and Development Centre has been equipped with highest quality equipment from top-notch manufacturers. We use several measuring stations where the quality of individual components of our products is attested.

List of major measuring stations in the Awenta Laboratory:

-

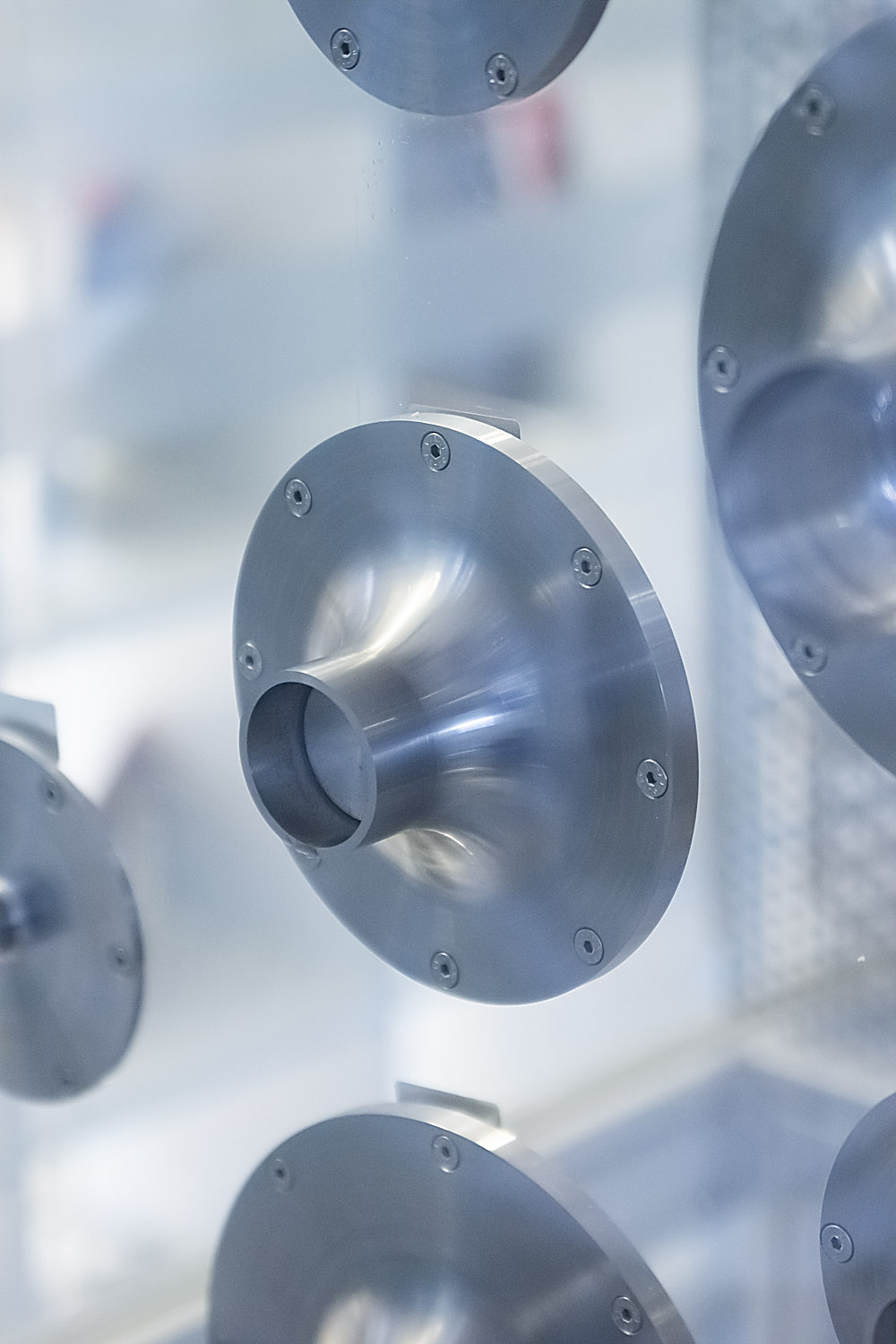

Anechoic chamber, equipped with appropriately soundproofed walls and microphones for measuring sound power (noise) within the range from 16 dB on.

-

Flow test rig for capacity and flow characteristics measurements, e.g. pressure drops in relation to flow rates of equipment and products.

-

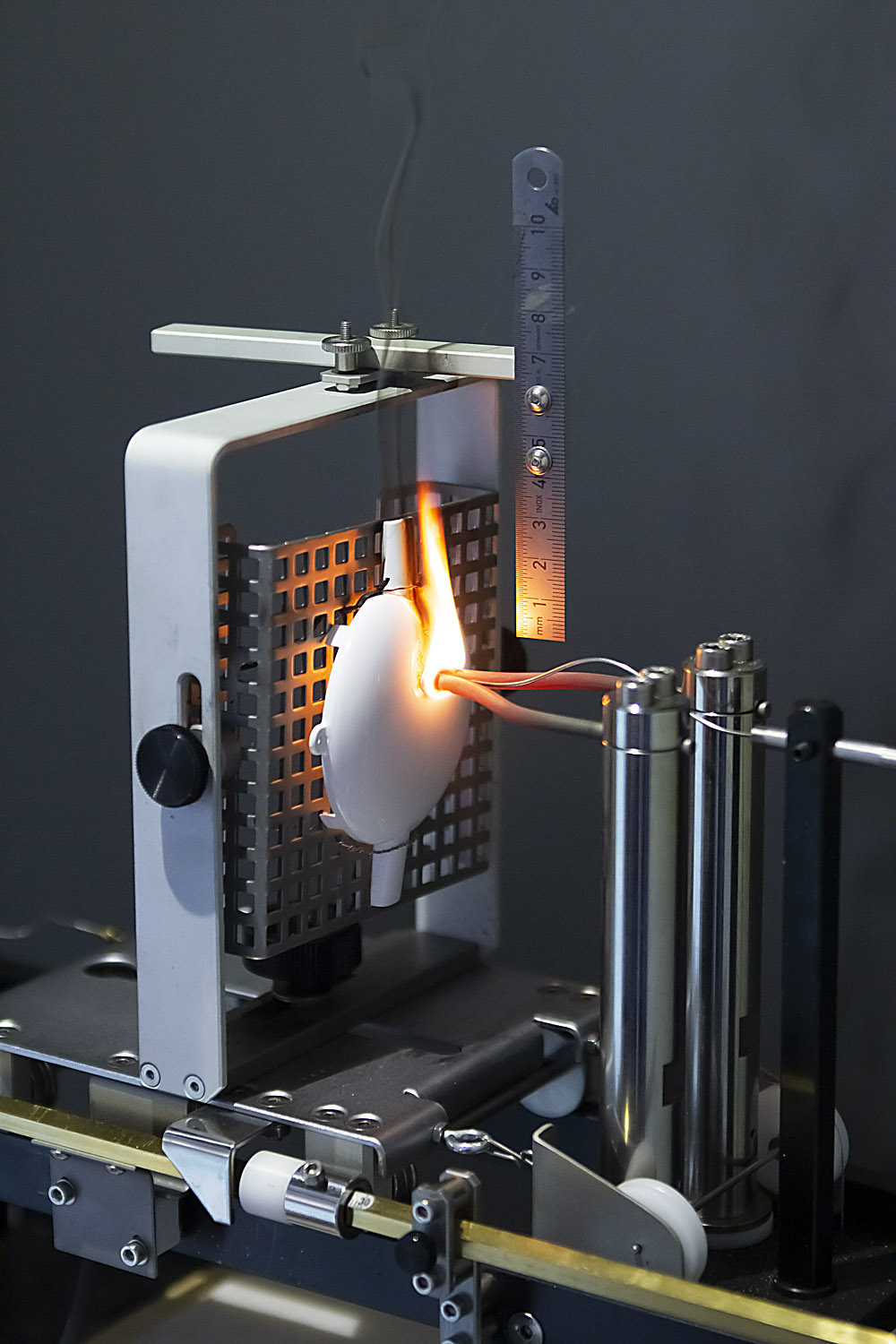

Fire hazard test station as described in the safety directive LVD PN-EN 60335-1 PN-EN 60335-2-80.

-

Test station for measuring the performance of equipment at elevated temperatures, also used for qualitative testing of raw materials before they enter production.

-

Test station for CTI and PTI measurements associated with creepage currents.

-

Electronic microscope.

-

Torque measurement for screwdriver calibration.

-

Test station for measuring safety in case of electric breakdown or continuity loss in a protective circuit.

-

Ageing chamber for testing the durability of products, in particular, how fan parameters are maintained over fan service life.

-

Enclosure water ingress protection testing station.

The Awenta Research and Development Centre and Laboratory runs a number of tests related to the product quality control and safety control, as set out in, for example:

-

Directive LVD PN-EN 60335-1 PN-EN 60335-2-80

-

ISO 9001:2008 for the scope of testing incoming materials and raw materials

List of major tests:

-

Measurement of the resistance to creepage currents (CTI) EN 60112

-

Measurement of the resistance to creepage currents (PTI) EN 60112

Measurement of compliance with safety requirements for the efficient connection of copper electrical conductors in the threaded terminals of fans. PN-EN 60999-1

-

Fire hazard using the glow wire method, as per PN-EN 60692-2-10

-

Resistance to excessive heat in ball pressure test, as per PN-EN 60695-10-2

-

Degrees of protection provided by enclosures (IP rating), as per PN EN 60529

-

Abnormal operating conditions – heating; determining winding temperature rise by resistance measurements

-

Current leak and dielectric strength

-

Power and current consumption

-

Measurements of insulation resistance

-

Measurement of motor winding resistance

-

Ageing testing

-

Determination of the processing shrinkage of plastics

Scope of the ErP Directive

-

Determination of the LwA sound power level based on sound pressure measurement, as per EN ISO 3744:2010

-

Determination of the flow rate of ventilation equipment, as per ISO 5801

We also comply with the requirements of the EN-PN ISO 9001:2015 for Quality Management System.